Discussion

2024-11-17

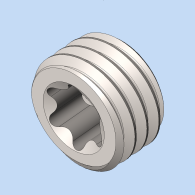

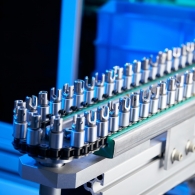

Critical Set Screw Manufacturing Quality Checks.This document outlines the key steps involved in the manufacturing process for high-quality set screws. The process

includes drilling and reaming holes, turning hexagonal or star holes, precisely finishing the outer circumference,

threading the outer diameter, and trimming the spindle cutoff surface. Critical quality checks ensure the final product

meets design specifications.

2024-11-17

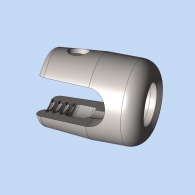

Key Quality Control of Machining U Head of Polyaxial Pedicle ScrewThe article details processing and quality controls for machining the U head of a poly-axial pedicle screw, emphasizing burr-free surfaces, precise thread and groove alignment, seamless component fit, and adherence to design specifications for functionality and compliance.

2024-11-17

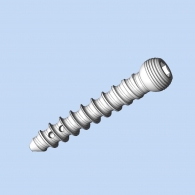

Key Control Aspects in CNC Machining of Spinal Polyaxial ScrewsFocus areas include ensuring precise thread alignment, controlling bone thread roughness, eliminating burrs, maintaining concentricity of hexagonal holes and threads, and adhering to spherical design specifications.

2024-11-17

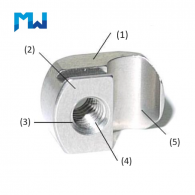

Cross-Link Component: Processing Steps and Key Quality ControlsThe processing of cross-link components involves precise milling, slotting, and thread tapping. Key quality controls focus on achieving burr-free, mark-free surfaces, flat end faces, smooth threads, and design-compliant tooth hole positions.

2024-11-17

Key AOI Points: Automatic Optical InspectionKey points of Automatic Optical Inspection (AOI) include the need for careful setup of inspection software and standards, continuous improvement of the software, and understanding that AOI reduces workload but cannot fully replace all inspection tasks.

2024-11-17

Achieving Precision in PEEK Spinal Cage Production: The Role of Specialized CNC Milling MachinesPrecision manufacturing of PEEK spinal cages relies on specialized CNC milling machines to ensure flawless surfaces, cost-efficient material use, and high-quality production tailored to specific cage dimensions.